New steam engines for paddle steamers and screw ships

Steam ships, especially paddle steamers, are very popular. "A means of transport that only has friends" was the title of an extensive article in a well-known Zurich daily newspaper on the worldwide popularity of steamships. The extraordinarily beautiful appearance of the classic paddle steamers, the elegant salons inside, the calm gliding over the water, the visible propulsion with its own dynamic and a good gastronomic offer make trips on steamships an unforgettable experience. Due to the age-related higher demand for staff, many of the elegant steamers were scrapped in the 50s and 60s and replaced by soulless motor ships. Just in time, thanks to private initiatives, some paddle steamers could be rescued and overhauled. In order to meet further demand and for economic reasons, it will now be necessary to modernise the existing steamers gently in order to reduce the additional costs caused by old technology. Automatic boilers have long been state of the art in industry and are increasingly becoming the standard on steamers. We have shown that remote-controlled steam engines are also possible with the revamp of the diesel-electric paddle ship "Montreux" on Lake Geneva. With today's technology, steam ships are thus possible which do not require more staff than comparable motor ships.

The modern steam technology offers some possibilities, which are not available to motor ships. Steam can be generated with any form of energy, so that CO2-neutral fuels can also be used. We are currently planning a new paddle steamer for the Hochrhein (Schaffhausen - Konstanz), which is to be equipped with a CO2-neutral pellet firing system.

In terms of sustainability, steam engines with a service life of 100 to 150 years (without any loss of performance!) cannot be topped. Today's diesel engines are often replaced on ships after only 10 years. Steam engines are also exemplary in terms of noise. Even at full load they work so quietly that the paddle steamers have open galleries from which passengers can watch the fascinating technology. The noise and vibrations of diesel engines, on the other hand, require comprehensive sound insulation.

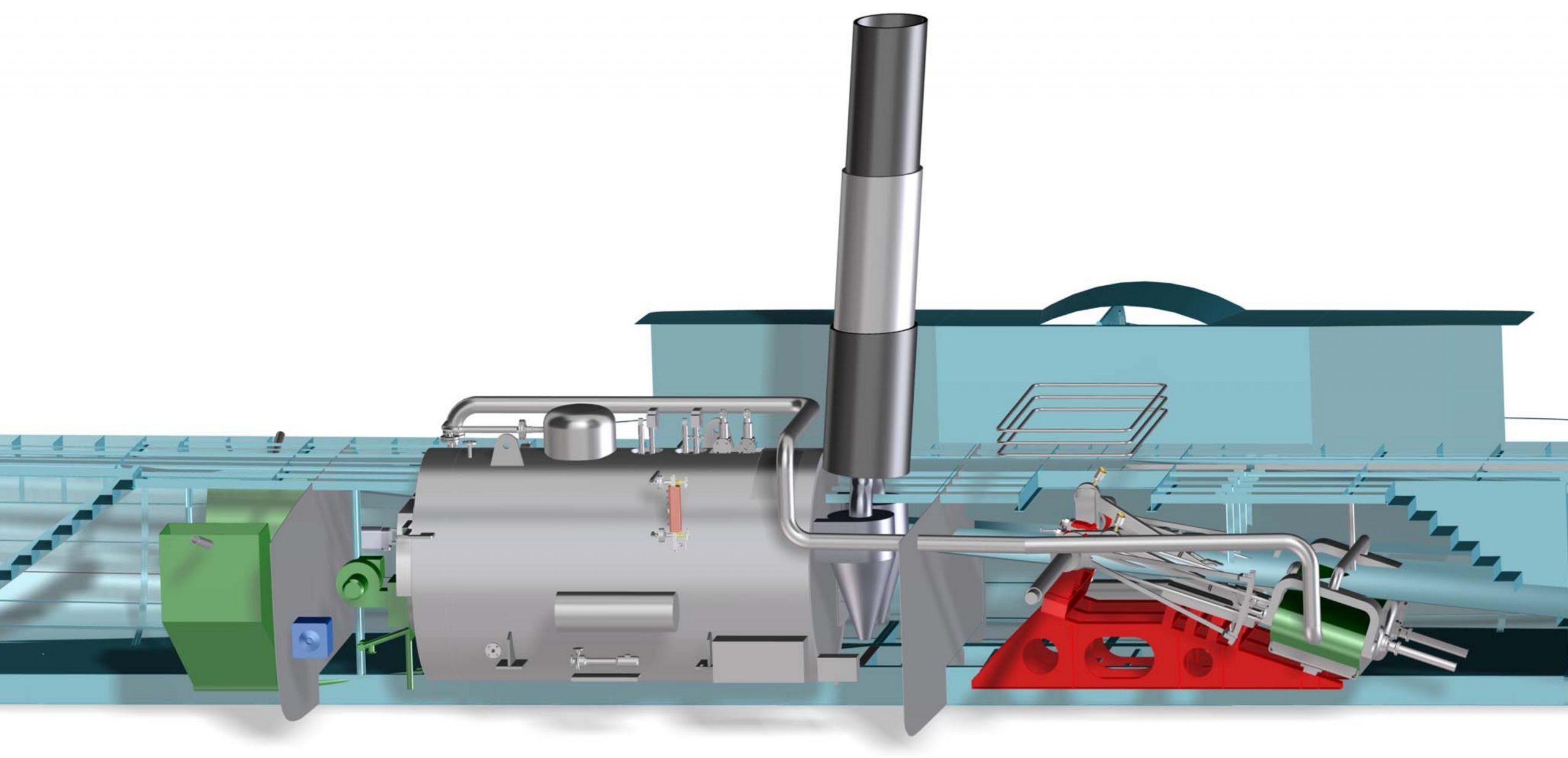

The layout drawing shows the projected steam drive of the new paddle steamer to be built for the Hochrhein. From left to right the green pellet bunker with the pellet burner, also drawn in green, is visible, followed by the large silver steam boiler, from which the superheated steam is conducted via the silver fresh steam pipe penetrating the bulkhead wall to the two-cylinder compound steam engine with exhaust steam condensation (red engine frame, green cylinder casing). The crankshaft directly drives the two paddle wheels.

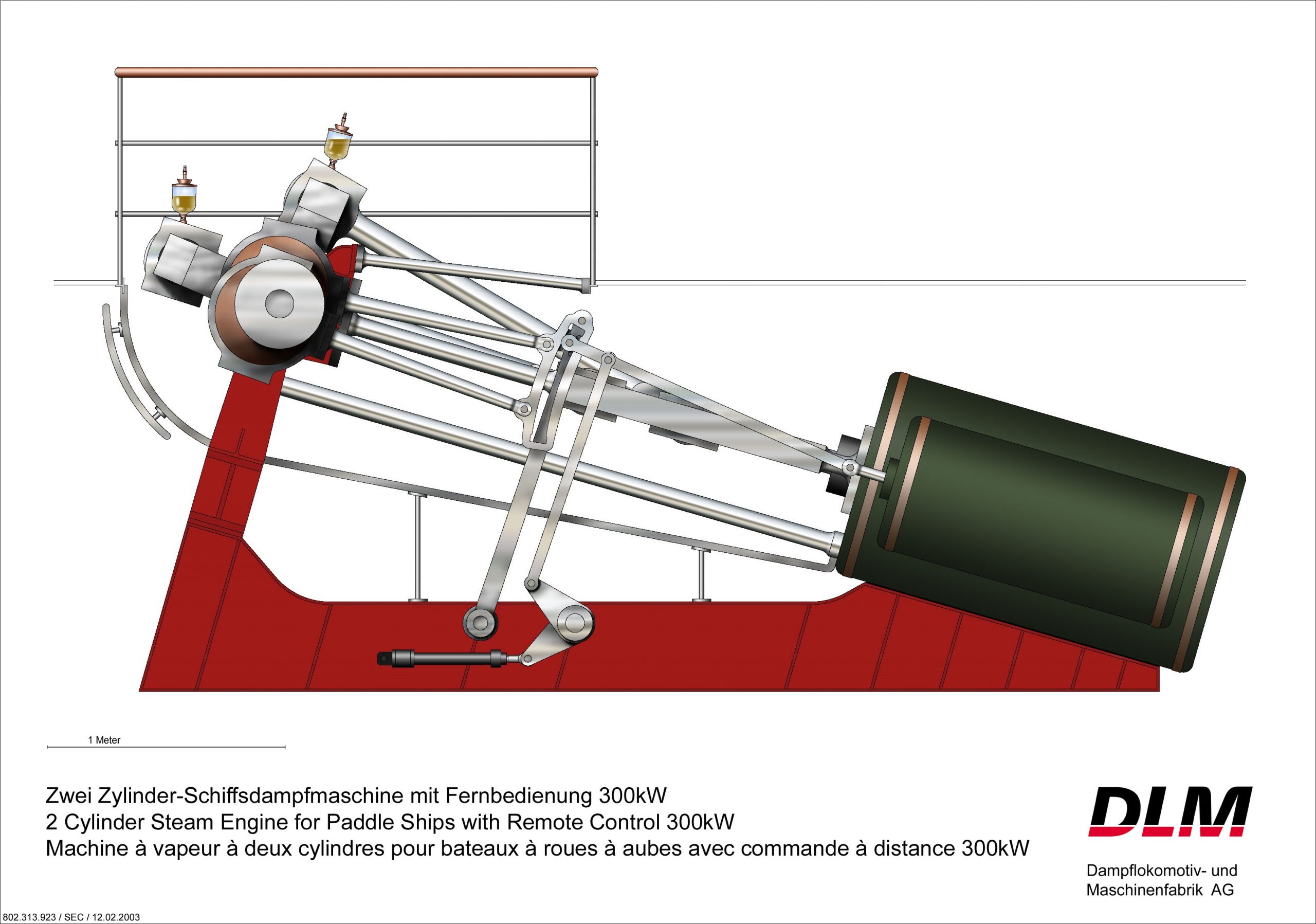

Project drawing of an inclined, low-speed two-cylinder compound steam engine for direct drive of the paddle wheels.

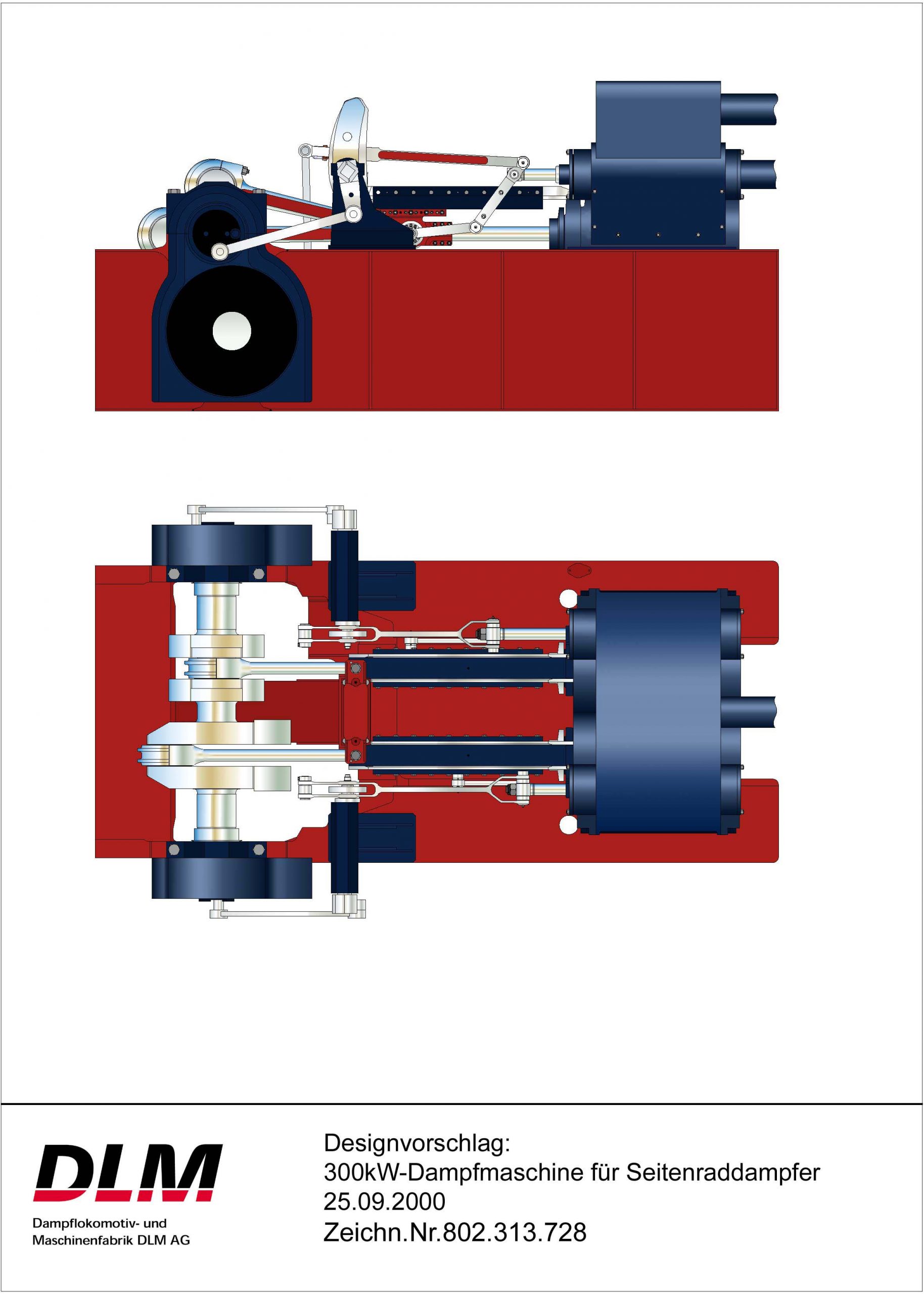

Project drawing of a compact, high-speed twin steam engine with reduction gear for driving the paddle wheels. Without the reduction gear, this steam engine is also suitable for screw steamers.